| Type | Insulation Materials | Where Applicable | Installation Method(s) | Advantages |

| Blanket: batts and rolls | •Fiberglass •Mineral (rock or slag) wool •Plastic fibers •Natural fibers | •Unfinished walls, including foundation walls •Floors and ceilings | Fitted between studs, joists, and beams. | Do-it-yourself. Suited for standard stud and joist spacing that is relatively free from obstructions. Relatively inexpensive. |

| Concrete block insulation and insulating concrete blocks | Foam board, to be placed on outside of wall (usually new construction) or inside of wall (existing homes): Some manufacturers incorporate foam beads or air into the concrete mix to increase R-values | •Unfinished walls, including foundation walls, for new construction or major renovations •Walls (insulating concrete blocks) | Require specialized skills Insulating concrete blocks are sometimes stacked without mortar (dry-stacked) and surface bonded. | Insulating cores increases wall R-value. Insulating outside of concrete block wall places mass inside conditioned space, which can moderate indoor temperatures. Autoclaved aerated concrete and autoclaved cellular concrete masonry units have 10 times the insulating value of conventional concrete. |

| Foam board or rigid foam | •Polystyrene •Polyisocyanurate •Polyurethane | •Unfinished walls, including foundation walls •Floors and ceilings •Unvented low-slope roofs | Interior applications: must be covered with 1/2-inch gypsum board or other building-code approved material for fire safety. Exterior applications: must be covered with weatherproof facing. | High insulating value for relatively little thickness. Can block thermal short circuits when installed continuously over frames or joists. |

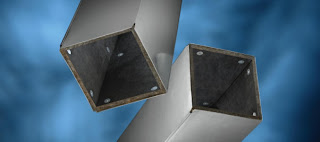

| Insulating concrete forms (ICFs) | •Foam boards or foam blocks | •Unfinished walls, including foundation walls for new construction | Installed as part of the building structure. | Insulation is literally built into the home's walls, creating high thermal resistance. |

| Loose-fill and blown-in | •Cellulose •Fiberglass •Mineral (rock or slag) wool | •Enclosed existing wall or open new wall cavities •Unfinished attic floors •Other hard-to-reach places | Blown into place using special equipment, sometimes poured in. | Good for adding insulation to existing finished areas, irregularly shaped areas, and around obstructions. |

| Reflective system | •Foil-faced kraft paper, plastic film, polyethylene bubbles, or cardboard | •Unfinished walls, ceilings, and floors | Foils, films, or papers fitted between wood-frame studs, joists, rafters, and beams. | Do-it-yourself. Suitable for framing at standard spacing. Bubble-form suitable if framing is irregular or if obstructions are present. Most effective at preventing downward heat flow, effectiveness depends on spacing. |

| Rigid fibrous or fiber insulation | •Fiberglass •Mineral (rock or slag) wool | •Ducts in unconditioned spaces •Other places requiring insulation that can withstand high temperatures | HVAC contractors fabricate the insulation into ducts either at their shops or at the job sites. | Can withstand high temperatures. |

| Sprayed foam and foamed-in-place | •Cementitious •Phenolic •Polyisocyanurate •Polyurethane | •Enclosed existing wall •Open new wall cavities •Unfinished attic floors | Applied using small spray containers or in larger quantities as a pressure sprayed (foamed-in-place) product. | Good for adding insulation to existing finished areas, irregularly shaped areas, and around obstructions. |

| Structural insulated panels (SIPs) | •Foam board or liquid foam insulation core •Straw core insulation | •Unfinished walls, ceilings, floors, and roofs for new construction | Construction workers fit SIPs together to form walls and roof of a house. | SIP-built houses provide superior and uniform insulation compared to more traditional construction methods; they also take less time to build. |

Insulated Concrete Forms

It is recommended to use this product if you hate everyone, especially your construction workers.

No comments:

Post a Comment